Name: Industry News

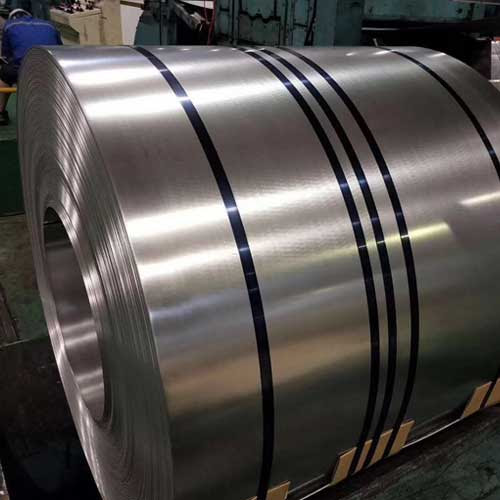

As global marine exploration advances, the demand for high-performance marine engineering stainless steel continues to grow. Specially formulated corrosion-resistant stainless steel has become the material of choice for critical deep-sea equipment materials, offering unparalleled durability in saline and high-pressure environments.

Modern marine-grade stainless steels (such as 316L and duplex varieties) incorporate chromium, nickel, and molybdenum to combat pitting and crevice corrosion. These alloys demonstrate exceptional performance in:

●Offshore oil/gas infrastructure

●Desalination plants

●Subsea pipelines and connectors

●Deep-sea sensors and ROV components

Leading stainless steel suppliers now provide ultra-high-nitrogen grades (e.g., 254 SMO) that withstand 4,000+ meter depths. Recent innovations include:

✔ Laser-clad corrosion barriers

✔ Smart coatings with pH-responsive inhibitors

✔ 3D-printed topology-optimized components

When selecting materials, engineers must consider:

• Chloride concentration

• Hydrostatic pressure effects

• Cathodic protection compatibility

• Microbial-influenced corrosion risks

Future-Proofing Marine Infrastructure

With proper alloy selection and surface treatment, stainless steel remains the most cost-effective solution for long-term marine service. Reputable suppliers now offer digital material passports and blockchain-tracked quality certificates to ensure traceability.