Name: Industry News

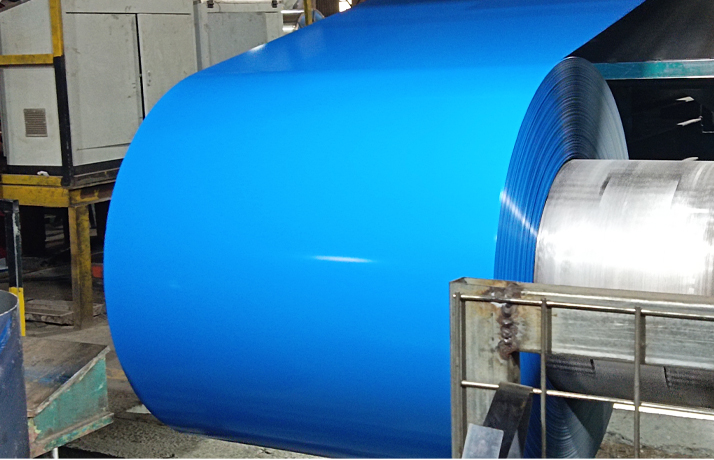

The North American construction industry is increasingly adopting pre-painted galvanized steel (PPGL) for light steel framing systems, driven by its superior durability, design flexibility, and environmental benefits. This material innovation is particularly valuable in commercial, residential, and industrial projects where both aesthetic appeal and structural performance are paramount.

Key Applications and Advantages

●Architectural Cladding Systems:

PPGL's color-coated finishes enable architects to create visually striking facades while providing weather resistance. The material's lightweight properties (30-40% lighter than traditional options) significantly reduce structural loads in mid-rise buildings.

●Roofing Solutions:

Advanced PVDF coatings on PPGL roofing panels offer exceptional UV resistance, maintaining color stability for 20+ years in harsh climates from Arizona to Alberta. Thermal reflective properties can reduce building cooling costs by up to 25%.

Performance Optimization:

●Corrosion Protection:

Dual-layer zinc-aluminum coatings combined with premium paint systems deliver 40+ years of service life in coastal environments

●Fire Resistance:

New intumescent coatings achieve Class A fire ratings without compromising weight advantages

●Sustainable Manufacturing:

Latest production techniques have reduced embodied carbon by 35% compared to 2015 benchmarks

Market Adoption Trends

The U.S. and Canada have seen 18% annual growth in PPGL usage for light steel construction since 2020, particularly in:

●Modular housing projects

●Retail big-box developments

●Agricultural storage facilities

As North American builders prioritize sustainable, cost-effective materials, performance-optimized PPGL stands out as a versatile solution for light steel construction. Ongoing advancements in coating technologies and manufacturing processes promise to further expand its applications across the construction sector.