Stainless steel section steel is a strip of steel formed by hot rolling, cold bending or extrusion. Common types include:

1. Stainless steel angle steel, L-shaped (equal/unequal sides), material 304, 316, mainly used for frame structures, equipment brackets, decorative keels

2. Stainless steel channel steel, [shaped, material 304H, 316L, mainly used for mechanical guide rails, conveyor supports, and building reinforcement

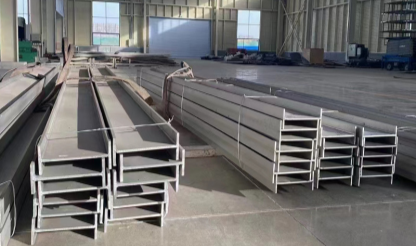

3. Stainless steel I-beam, I-shaped, material 316L, 2205 duplex steel, mainly used for heavy load-bearing structures (bridges, factory beams and columns)

4. Stainless steel square tube, square hollow, material 304, 201, mainly used for guardrails, furniture frames, display racks

5. Stainless steel round steel, solid round, material 303, 416 (easy to cut), mainly used for shaft parts, bolt blanks, hardware

6. Stainless steel flat steel, rectangular flat, material 430, 304, mainly used for decorative trim, gaskets, tool blanks

7. The selection of stainless steel needs to be balanced Corrosion resistance, strength, cost and processing performance:

General scenarios: 304 angle steel/square tube (high cost performance).

Harsh environment: 316L or 2205 I-beam/channel steel (high corrosion resistance).

Decorative use: surface polishing or color plating.